Darby Dunn, the Vice President of operations at Commonwealth Fusion Systems.

Photo courtesy Commonwealth Fusion Systems

From March 2009 to December 2018, Darby Dunn held a handful of engineering and production roles at SpaceX.

“In one role in particular, my unofficial title was ‘Mother of Dragons,'” Dunn told CNBC in an interview in Devens, Massachusetts. “In that role, I was leading the build out of our new manufacturing facilities for the crew Dragon vehicle.”

While she was overseeing production of the Dragon spacecraft, SpaceX went from ramping up production to making its very first spacecraft, and then to sending cargo to the International Space Station on it regularly, Dunn says.

Building rockets is a very cool thing to do. But in January 2019, Dunn started work at Commonwealth Fusion Systems, a startup that is attempting to commercialize nuclear fusion as an energy source. Fusion is the way the sun and the stars make energy. If it can be harnessed here on Earth, it would provide virtually unlimited clean energy.

But so far, fusion at scale remains in the realm of science fiction.

Darby Dunn with the SpaceX Dragon rocket.

Photo courtesy Darby Dunn

Dunn says she made the switch from building rockets to working on making fusion energy a reality because she wants to see the impact of her efforts in her lifetime.

“I very much believe SpaceX will make life multiplanetary. I don’t know how much of that I’ll see in my lifetime,” Dunn, 37, told CNBC at the end of May.

But Dunn has spent large chunks of her life living in California, where SpaceX is based, and has very much seen the effects of climate change in the shape of wildfires and mudslides stemming from extreme rain.

“For me, it really came down to wanting to use my energy to clean up the planet instead of get off it. So that was the the huge shift for me to come to CFS,” Dunn told CNBC.

Joining Commonwealth Fusion Systems in the early stages, as its 10th employee, has allowed her to see a different stage on the journey of company growth, too.

“We’re a 5-year-old company with 500 employees,” Dunn told CNBC. “I joined SpaceX when it was 6 years old with about 500 employees. So I’ve actually been able to see the entire era that I didn’t get to experience at SpaceX and doing so at CFS.”

The Commonwealth Fusion Systems campus in Devens, Mass.

Photo courtesy Commonwealth Fusion Systems

A key difference between the two jobs is the maturity of the respective industries.

“The aerospace industry has been around for a long time. So building a rocket engine, the mechanics of it look really similar, or the structure itself, or the physics of how it works is all very, very well studied and very well understood,” Dunn told CNBC.

Fusion machines have been studied in academic settings and research labs since the early 1950s, but the entire industry is just at the very first stages of trying to prove that the science can have commercial applications. It’s being a part of that excitement that was a big draw for Dunn.

Of course, there are plenty of skeptics who say the industry is the equivalent of Don Quixote tilting at his windmills. But Dunn says her time at SpaceX prepared her to face the skeptics.

“When Elon said publicly that we were going to launch and land rockets back from space, everybody said, ‘That’s not possible! You can’t do it!'” Dunn said, referencing SpaceX CEO Elon Musk. SpaceX’s response was that the laws of physics say it is possible and so they were going to prove it, Dunn told CNBC.

“It took many attempts, a lot of learning, a lot of iterations on our software, many failed attempts off the boat — and then we did it. And then we did it again. And we did it again. And we did it again,” she said.

Darby Dunn, vice president of operations at Commonwealth Fusion Systems.

Photo courtesy Commonwealth Fusion Systems

“Now it’s gotten to the point where you’ve seen the aerospace industry shift to say, ‘Well, why aren’t these other companies also lending their rockets back from space?’ It’s completely changed the way that people are looking at it. They first said, ‘It wasn’t possible. Then, ‘OK, it is possible.’ And now it is saying, ‘Well, why isn’t everybody else jumping in?'”

Dunn is looking to be part of that kind of transition for the fusion industry at Commonwealth.

Speed is key

Dunn is the vice president of operations, which covers manufacturing, safety, quality and facilities. She’s helping Commonwealth make the transition from research and development-scale processes to manufacturing and full-scale production.

The company spun out of research at Massachusetts Institute of Technology and the company’s goal is to build 10,000 fusion power plants around the world by 2050, Dunn told CNBC.

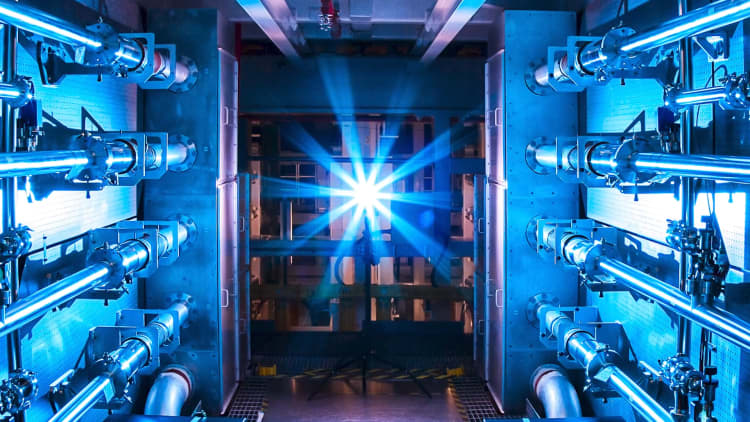

First, however, Commonwealth has to prove that it can generate more energy in its fusion reactor than is necessary to get the reaction started, a key threshold for the fusion industry called “ignition.” To do that, the company is currently building its SPARC tokamak — a device that will help contain and control the fusion reaction. The company plans to turn it on in 2025 and demonstrate net energy shortly thereafter.

To build SPARC, Commonwealth needs to make a lot of magnets using high-temperature superconducting tape.

The advanced manufacturing facility located at the Commonwealth Fusion Systems campus in Devens, Massachusetts, where magnets are manufactured.

Photo courtesy Commonwealth Fusion Systems

“The cool part of this building is that the concept for it started out as a doodle that I made on a whiteboard three years ago,” Dunn told CNBC. “To see the steel beams going up, walls going up, concrete getting poured, it’s a whole vision coming to life, which is super exciting.”

To fund the construction, Commonwealth has raised more than $2 billion from investors including Bill Gates, Google, Khosla Ventures and Lowercarbon Capital.

Even as Commonwealth is figuring out how to make one magnet, Dunn is leading her team to develop manufacturing processes that can eventually scale to a process that looks like an automotive assembly line, she told CNBC.

Moving fast is a priority for Dunn, and the rest of the team. After building the demonstration fusion machine, SPARC, the company aims to build a bigger version called ARC, which it says is going to deliver electricity to the grid. The aim is to have ARC online in the 2030s.

“The biggest thing I think about a lot is time, about how fast can we go,” Dunn told CNBC. “The sooner we can get the magnets built, the sooner we can build SPARC, the sooner we can turn it on, the sooner we can get in net energy, the sooner we get to our first ARC. So I think that’s probably the element that I think about the most.”

Darby Dunn in the Commonwealth Fusion Systems advanced manufacturing facility.

Photo courtesy Commonwealth Fusion Systems

Speed matters because critics argue that it will take too long to get fusion to work as an energy source to meaningfully contribute to the very urgent need to reduce greenhouse gas emissions.

Top climate scientists at the United Nations Intergovernmental Panel on Climate Change have said that to have “no or limited” overshoot of the 1.5 degrees Celsius warming above preindustrial levels will require a 45% reduction in carbon dioxide emissions by 2030 compared to 2010 levels and hitting net zero around 2050.

“I have asked myself, ‘Why am I doing fusion as opposed to something that is going to be deployed next year?'” she told CNBC. “For me, it comes down to the fact that fusion is the most energy dense reaction in our solar system.”

But she does not believe fusion should be the only solution.

“I very much believe in in solar power and wind and a lot of other renewables — that we absolutely need those. We need those deployed now. We need those deployed all over the world,” Dunn told CNBC. “But I don’t think they will be enough to get us to 2050 and beyond.”

Electric cars, heat pumps, green steel and green cement all depend on having large quantities of clean electricity. Its Dunn’s focus to build the energy sources that the world will need in the decades and centuries to come.

If Commonwealth is going to deliver that solution, though, Dunn first has to make a whole lot of very high-powered magnets.

“My own personal opinion is I’m going to keep on keeping on — keep on building. And we have a poster in the back stairwell that says, ‘Keep calm and fuse on,” Dunn told CNBC. “Regardless of what the outside world is saying, we are working every day towards our mission of getting net-positive energy from fusion. And I look forward to proving that to the world in a couple of years.”